Home > Products > Copper Nickel Products > C71500 CuNi 70-30 Copper Nickel Flange

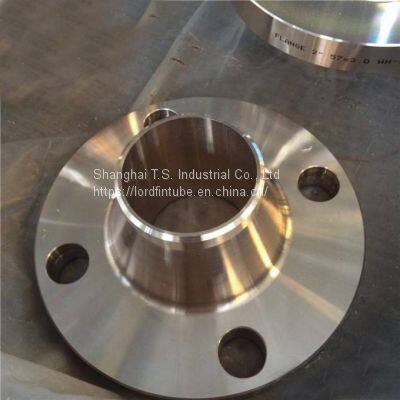

C71500 CuNi 70-30 Copper Nickel Flange

- 1500 Piece / Pieces per Month

- shanghai

- T/T L/C

- 50 days

You May Like

Product Details

| Brand Name | None | Place of Origin | China | |

| Model Number | 131 | Shape | Flange | |

| Application | offshore, oil field, shipbuilding, water system, natural gas, pipeline engineering, electric power, etc. | Chemical Composition | Mn 1.00max, Ni 29.00-33.00, Fe 0.40-1.00, Zn 1.00max, Pb 0.05max, Cu rest | |

| Dimensions | Sizes: 1/2”-60” Class: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc. | Material | C71500 CuNi 70-30 Copper Nickel |

Product Description

C71500 copper-nickel, also known as 70/30 copper-nickel, offers good corrosion resistance, especially in marine saltwater environments. The primary forged copper-nickel alloys selected for use in seawater service contain 10% or 30% nickel. They also have the important additions of iron and manganese, which are necessary to maintain good corrosion resistance. Although this alloy was known to the Chinese in the 9th century, it did not become popular until the 1920s when it was developed for use in the Navy's seawater condenser systems. It retains its strength well at moderate temperatures, has good cold and hot workability, and is easy to weld.

C71500 copper-nickel is used for brine piping and fittings, refrigerator and condenser components, welding wire and boiler components, brine flanges, heat exchangers and cooling units, welded backing rings, etc.

Specifications of C71500 CuNi 70-30 Copper Nickel Flange

Specifications: ASTM B151/ASTM SB151

Standards: ASTM, ASME, DIN, EN, ANSI, BS, GOST

Flange Face Type: Flate Face (FF), Raised Face (RF)

Flange Type: Welded Neck Flange, Slip On Flange, Blind Flange, Socket Welded Flange, Lap Joint Flange, etc.

Material: C71500 CuNi 70-30

Sizes: 1/2”-60”

Class: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Payment Terms: T/T, L/C

Delivery Time: As per quantity ordered

Chemical Composition (%) of C71500 CuNi 70-30 Copper Nickel Flange

Mn, max | Pb, max | Ni | Fe | Zn, max | Cu |

1.00 | 0.05 | 29.00-33.00 | 0.40-1.00 | 1.00 | Rest |

Mechanical Properties of C71500 CuNi 70-30 Copper Nickel Flange

Tensile Strength | Yield Strength (0.2%Offset) | Elongation (%) |

50000 psi | 20000 psi | 30 |

Physical Properties of C71500 CuNi 70-30 Copper Nickel Flange

Density | Melting Point | Electrical Conductivity | Thermal Conductivity | Modulus of Rigidity | Modulus of Elasticity in Tension |

0.323 lb/in3 at 68℉ | 2260℉ | 4.6% IACS at 68°F | 17 Btu/ sq ft/ ft hr/ °F at 68°F | 8300 ksi | 22000 ksi |

Pressure Rating of C71500 CuNi 70-30 Copper Nickel Flange

Temperature ℃ | Pressure by Classes | ||||||

150# | 300# | 400# | 600# | 900# | 1500# | 2500# | |

-29 - 38 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

50 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

100 | 17.7 | 51.5 | 68.7 | 103.0 | 154.6 | 257.6 | 429.4 |

150 | 15.8 | 50.3 | 66.8 | 100..3 | 150.6 | 250.8 | 418.2 |

200 | 13.8 | 48.6 | 64.8 | 97.2 | 145.8 | 243.4 | 405.4 |

250 | 12.1 | 46.30 | 61.7 | 92.7 | 139.0 | 231.8 | 386.2 |

300 | 10.2 | 42.9 | 57.0 | 85.7 | 128.6 | 214.4 | 357.1 |

325 | 9.3 | 41.4 | 55.0 | 82.6 | 124.0 | 206.6 | 344.3 |

350 | 8.4 | 40.3 | 53.6 | 80.4 | 120.7 | 201.1 | 335.3 |

375 | 7.4 | 38.9 | 51.6 | 77.6 | 116.5 | 194.1 | 323.2 |

400 | 6.5 | 36.5 | 48.9 | 73.3 | 109.8 | 183.1 | 304.9 |

425 | 5.5 | 35.2 | 46.5 | 70.0 | 105.1 | 175.1 | 291.6 |

450 | 4.6 | 33.7 | 45.1 | 67.7 | 101.4 | 169.0 | 281.8 |

475 | 3.7 | 31.7 | 42.3 | 63.4 | 95.1 | 158.2 | 263.9 |

500 | 2.8 | 28.2 | 37.6 | 56.5 | 84.7 | 140.9 | 235.0 |

538 | 1.4 | 16.5 | 22.1 | 33.1 | 49.6 | 82.7 | 137.9 |

550 | - | 13.9 | 18.6 | 27.9 | 41.8 | 69.7 | 116.2 |

575 | - | 9.4 | 12.6 | 18.9 | 28.3 | 47.2 | 78.6 |

600 | - | 6.6 | 8.9 | 13.3 | 19.9 | 33.2 | 55.3 |

625 | - | 5.1 | 6.8 | 10.3 | 15.4 | 25.7 | 42.8 |

650 | - | 4.7 | 6.3 | 9.5 | 14.2 | 23.6 | 39.4 |

Equivalent Grades of C71500 CuNi 70-30 Copper Nickel Flange

STANDARD | WERKSTOFF NR. | UNS |

CuNi 70-30 | 2.0882 | C71500 |

Features of C71500 CuNi 70-30 Copper Nickel Flange

- Good corrosion resistance

- Good cold and hot workability

- Easy to weld

- High hardness

- Good ductility

Application of C71500 CuNi 70-30 Copper Nickel Flange

Used in offshore, oil field, shipbuilding, water system, natural gas, pipeline engineering, electric power, etc.

Contact Us

- Shanghai T.S. Industrial Co., Ltd

- Contact nameEstela Chat Now

Product Categories

| Finned Tube | Tube Sheet | U bend Tube | Steel Tube |

| Aluminium Products | Stainless Steel Products | Copper Nickel Products | Titanium Products |

New Products

-

M Type Fin Tube | Medium-Finned Tube

-

WO Type Fin Tube | Welded On Solid Finned Tube

-

HFW Solid Finned Tube, High Frequency Welded Solid Finned

-

I Type Fin Tube | Tension Wound Finned Tube

-

Laser Welding Finned Tube | Laser Welded Stainless Fin Tube

-

L, LL, KL Type Fin Tube | DL Fin Tube

-

G Type Fin Tube | Embedded Finned Tube

-

S Type Fin Tube | Square Finned Tube

-

Embedded Finned Tube | G Type Fin Tubes

-

WOS Type Fin Tube | Welded On Serrated Finned Tube

-

LFW Type Fin Tube | Longitudinal Finned Tube

-

HY Type Fin Tube | Extruded Finned Tube

-

HYS Type Fin Tube | Extruded Serrated Finned Tube

-

KL Type Finned Tube, Knurled Finned Tubes

-

Spiral Wound Finned Tube|Galvanized Finned Tube | Hot dip galvanized cold wound finned tube

-

LL Finned Tube , Overlapped L Type Fin Tube

-

N Type Fin Tube | Low Finned Tube

-

Three-dimensional ribbed tube, 3-D Finned Tube

-

Extruded Fin Tube, Extruded Fin Tube, Aluminum Finned Tubes

-

H Finned Tube; Square Finned Tube

-

Rectangular Finned Tubes, Double H Fin Tubes, Square Fin Pipe,

-

Inner finned tube; Internally finned tube

-

High Flux Tube, High Flux Tubes, High Flux Heat Exchange Tube

-

Single Row Flat Fin Tube|Single Row Finned Tube

Popular Searches

Recommended Products

- 2026 China (Guangzhou) Int’l Metal & Metallurgy Industry Exhibition

- stainless steel seamless pipe

- stainless steel seamless pipe

- 904L stainless steel seamless pipe

- Silicon Carbide resistors SiC resistors

- Electric heating molybdenum disilicide type L

- M Type Silicon Carbide Heating Elements

- Zirconia Sintering Furnace U shape MoSi2 Heating Element 1850C

- SiC heating elements-spiral groove Bar for higher temperatures (3000°F)

- Super pure 1850C MoSi2 heater heating element

- Dental Sintering Furnace U shape MoSi2 Heating Element For Zirkonzahn 600

- Dental zirconia Sintering furnace use Molybdenum Disilicide (MoSi2) Heating Elements

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Black Metal & Products

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Estela

Hi there! Welcome to my shop. Let me know if you have any questions.

Estela

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile